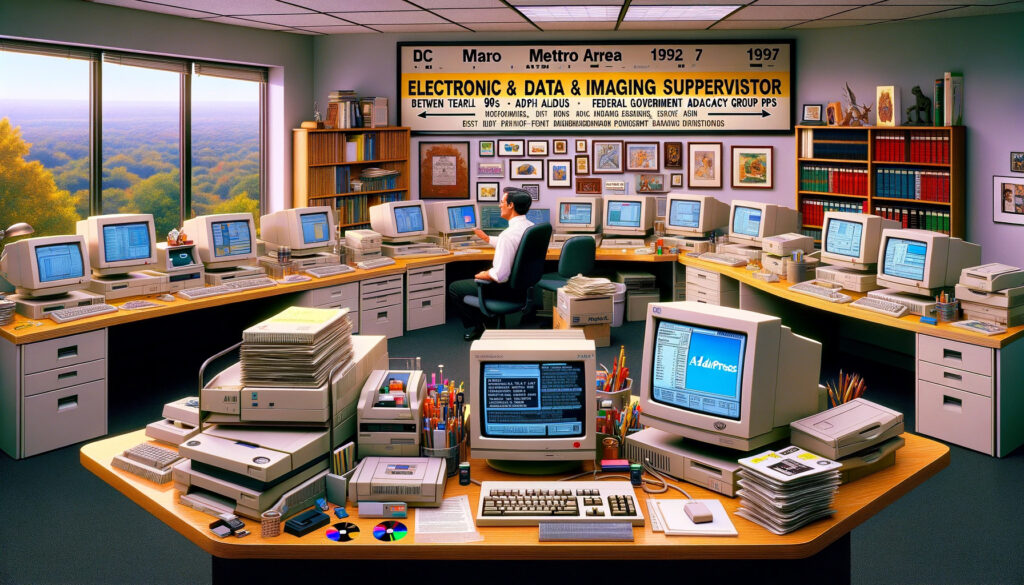

Electronic Data & Imaging Department Supervisor

Company: Weadon Printing Services, Inc.

Timeline: 1992 – 1997

Location: Alexandria, Virginia

Hardware:

Agfa, Apple (Beige) Server, LinoType Hell, SyQuest Removable Cartridge Drives, Travan Digital Audio Tape (DAT) for storage

Software:

Adobe Acrobat, Dantz Retrospect, PostScript, Aldus PageMaker, QuarkXPress

Experience:

First hired as the second shift Electronic Data & Imaging Department (EDID) Supervisor, responsible for ensuring the Printing Presses were manufacturing materials over the night shift; often late breaking and high-pressure print jobs that were needed as soon as possible the next day. Our clients were Trade Associations, Non Profits, Lobbying, Congressional Advocacy all at a time before the Internet as we know it today; there were Bulletin Boards systems and we were just implementing File Transfer Protocol Transfer methods using dial-up networking technology .

AppleTalk Networking: Network Setup and Maintenance, AppleTalk networks, which were the primary means of connecting Macs used for prepress tasks like layout and design in our Local Area Network.

File Sharing and Transfer: Ensured smooth file sharing and transfer between Macs and other devices, such as imagesetters and storage systems.

Troubleshooting: Diagnosing and resolving network issues to ensure uninterrupted workflows.

Backup and Archiving: Implementing and managing backup strategies using Dantz Retrospect software and digital tape drives to safeguard critical prepress data and restore old jobs, not only was this a Business Continuity Preparedness (BCP), this experience and practice of electronic – digital storing and retrieval would prove important for years-and-years to come until present day when we all know how important dat backup is. What I mean to say is, the practice of storing and retrieval of data, is in essence BCP- Disaster Recovery in theory and practice each and every day in the Printing and publishing manufacturing business.

Data Recovery: Restoring files from backups in case of accidental deletion or data corruption.

Storage Management: Optimizing storage capacity and ensuring the integrity of archived data.

Outputting Film: Operating Agfa imagesetters to produce high-resolution film from digital files, which were then used to create printing plates.

Daily Calibration and Maintenance: Calibrating imagesetters to ensure accurate color reproduction and maintaining them for optimal performance.

Troubleshooting: Addressing issues like film jams, exposure problems, and resolution errors.

Adobe PostScript:

File Conversion: Converting files from various formats to PostScript, the page description language used by imagesetters and printers.

Font Management: Handling PostScript fonts, ensuring their proper installation and embedding in documents.

Troubleshooting: Resolving PostScript errors that could affect output quality.

Trapping and Color Management:

Trapping Setup: Implementing trapping techniques in prepress software to compensate for misregistration during printing, preventing gaps or overlaps between colors.

Color Calibration: Calibrating monitors, scanners, and imagesetters to ensure consistent color reproduction across devices.

Proofing: Generating color proofs to verify color accuracy before final printing.

Additional Responsibilities:

Training: Training prepress operators and designers on new digital workflows and technologies.

Workflow Optimization: Streamlining prepress processes to improve efficiency and reduce turnaround times.

Quality Control: Ensuring the accuracy and quality of prepress files before they were sent to the printing press.

In 1992, the EDID was a dynamic and evolving department, as the printing industry was rapidly adopting digital technologies. I played a crucial role in this transition, bridging the gap between traditional and digital prepress methods. This expertise was essential for ensuring profitable workflows, high-quality output, and the successful integration of new technologies into our printing process. Prepress technology was undergoing a significant transformation, marking a shift from traditional, analog methods to digital processes.

Key Technologies:

Desktop Publishing (DTP) Software: Applications like QuarkXPress and PageMaker revolutionized layout and design, allowing for greater flexibility and control compared to manual paste-up.

Image Scanners: High-resolution scanners digitized photographs and illustrations, enabling their integration into digital layouts.

Imagesetters: These devices replaced traditional typesetting machines, outputting high-resolution film from digital files for plate-making.

Color Management Systems: Emerging technologies helped to calibrate and control color across devices, ensuring consistency from screen to print.

Impact on the Industry:

Increased Efficiency: Digital workflows streamlined prepress tasks, reducing time and labor costs.

Improved Quality: Digital processes offered greater precision and control, resulting in higher-quality printed materials.

New Creative Possibilities: DTP software opened up new avenues for design and experimentation.

Challenges:

Cost: Early digital prepress systems were expensive, limiting their adoption to larger printers and publishers.

Learning Curve: Traditional prepress professionals had to acquire new skills to adapt to digital workflows.

Standardization: The industry was still developing standards for file formats and color management, leading to compatibility issues.

Overall, electronic prepress technology in 1992 represented a pivotal moment in the printing industry. While the transition was not without challenges, it laid the foundation for the digital workflows that are now commonplace. This shift ultimately democratized publishing, making it more accessible to a wider range of individuals and businesses and I was there along for the ride with a front row seat.